Question: How can I automate my FEA model check and validation?

Answer: Most companies know that Finite Element Analysis (FEA) can be a very powerful and beneficial tool to support their product development process. In addition, most of these companies know that it can be a dangerous tool if not used properly. Any successful strategy that includes FEA must seriously consider model verifications as a core enabler and apply them in a systematic fashion. Without it, the technology and automated custom processes investments might very well lead to wrong answers, faster.

The impact of poor FEA quality can be significant. It can produce bad designs which in turn lead to:

- Potential product failure

- Significantly delayed milestones and product delivery

- Warranty and liability issues

- Missed customer expectations

It can also lead to over-designed products which use too much material, increase product weight, increase cost, and ultimately lose business to the competition.

Also, late identification of design flaws can cause expensive fixes and significantly delayed product releases. The work may need to be redone, or worse, require recall of components already in use worldwide, raising safety concerns with dramatic cascading impacts on the product line, delays in delivery and on the next product line.

The question is then, how can companies quickly and easily perform checks to ensure high level FEA quality throughout their enterprise?

Typical Sources of FEA Model Quality Issues

There can be many sources of FEA model quality issues, depending on the modeling practices used to represent a particular physical system. That being said, here are some key areas where problems typically arise:

- Materials and properties

- Wrong property values entered or material different than specified

- Wrong material thickness entered

- Connections and Constraints

- Components in assemblies not connected

- Components or assemblies over or under constrained

- Loading Conditions

- Element Quality

Several other common mistakes are:

- Improper element usage and model conditioning issues

- Not requesting the correct results for post-processing and analysis

- Not using the correct analysis specific parameters

All of these can turn an analysis into a significant waste of time, if not, bad product design.

How Do These Errors Happen and How Can This Be Avoided?

Most of these problems seem pretty basic, but how can they occur?

Problems typically occur when the analyst or engineer:

- Is new to FEA or is not familiar with the best modeling practices for a particular physical system.

- Is trying to work with very large and complex system models that require a lot of bookkeeping.

- Is pressured to turn around results very quickly.

- Stress analysis department lacks the definitions of good practice standards.

Under these circumstances it can be quite easy to make a modeling mistake, even for the most experienced FE analyst.

There are typically two ways to avoid or catch these problems before critical computing resources are used for a simulation:

- Use best FEA modeling practices and processes.

- Perform model quality tests and validation checks.

Performing model quality and validation checks manually can be time consuming. And when it comes to high pressure situations where the CAE team is being pushed to produce results, FE analysts may lack the time to perform systematically all of the recommended model quality checks. Furthermore, this is why automating model quality and validation checks can be highly valuable to guarantee high QA while ensuring high confidence FEA results.

Automating FEA Model Quality and Validation Checks Using SimXpert and Template Builder

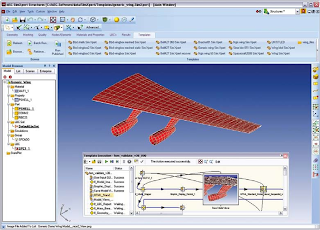

With SimXpert and its Template Builder Workspace, it is now possible for any user to setup their own FEA quality check process. Ideally, senior analysts can develop standard model quality tests to be used consistently by the entire analysis team.

The Template Builder Workspace was developed to support a full spectrum of users, from FEA experts that don’t have an affinity to programming, to programming specialists, by providing drag-and-drop capabilities as well as script editors and access to SimXpert APIs for flexible and custom solutions.

Using SimXpert’s extensive library of Actions covering the analysis workspace interface commands, users can create a standard process by simply dragging and dropping Actions into the 2D Workspace and connecting them together. Or, the user can use one of the SimXpert analysis workspaces to record the process actions using the Macro Record functionality, which will automatically chain the Action steps together. The resulting macro becomes the foundation template which can then be edited and further expanded in the Template Builder Workspace.

Actions carry Input and Output in a graphical fashion allowing the expert analyst to easily and explicitly capture and share simulation processes while greatly limiting the amount of programming. Once inputs are defined, the specific user interface GUI can be automatically created in one click.

For extended flexibility and ultimate customization, user defined actions can be created using Python scripts. These Actions can complement the template with user defined functionality querying any database object or linking to an external process or any third party application via APIs, as well as accessing the SimXpert API layer.

Here are some of the unique capabilities and advantages to using SimXpert Templates and the Template Builder workspace:

- Use Macro Record to capture and string together a series of modeling actions and build basic starting templates which can be directly loaded into the Template Builder Workspace.

- Use the Template Builder Workspace to create, edit, and publish FEA process templates.

- Use Actions from an extensive library of FEA modeling actions.

- Nesting and sharing of sub-templates in other processes – reuse existing templates as components of new templates.

- Looping of actions to process a list of parts or multiple load cases, for example

- Create user specific actions with Python scripts.

- Convert templates to Python scripts.

- Access to SimXpert API layer.

- Automatically create GUI Dialogue Windows to query user during template run

- Capture 3D Graphical Snapshots of the CAE model at different stages of the process for progress checks

- Create interactive, semi or fully automatic FEA processes

Once the Template is complete, the user can publish this to SimManager for simulation deployment or it can be maintained on a local or served file system for local and remote access.

The templates can then be run within the SimXpert Workspace, using the Template Runner. Individual or portions of template’s steps can be run, or the user can run the entire process automatically. While running, progress is followed in Tree View or Process View modes or both.

Standard CAE Model Checking Process Applicable to any Industry Designing Structural Systems

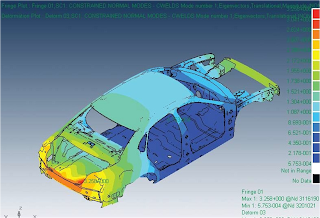

Here is an example of a SimXpert Template, which performs some of the standard FEA model quality checks recommended by MSC’s lead application engineers and widely accepted throughout the world in both the Automotive and Aerospace industries. This set of model verifications of structural system models is generic and can be applied to most industrial applications. The objective of the template is to allow the analysts to select the level of validation tests required, using parameters specific to MSC Nastran based simulations.

The benefit of this template is twofold: first, it significantly reduces the amount of time to perform a systematic and detailed quality check; and second, it also generates a complete and comprehensive HTML report.

Here’s a quick overview of the basic verifications performed by the template:

- Starting Dialogue Form – contains internal specification default check values; lets the user choose the types of validation checks to perform on any given model

- Quality Checks – User selects checks from the following list:

| Model Quality Process Checks | ||

| ✔ | Generate Model Images | Automatically capture and report standard views as well as user defined views; an otherwise manual time consuming effort |

| ✔ | Reports reference boundary conditions | Useful to transfer model for system level integration |

| ✔ | Weight Check | Provides a quick check to:

|

| ✔ | Element Quality | Checks Check for elements that may affect simulation results quality. Checks include:

|

| ✔ | Static Check | Apply gravity load to the model to check for:

|

| ✔ | Free-Free Modal Conditioning Check |

|

| ✔ | Modal Analysis Summary |

|

| ✔ | Free Thermal Expansion Check |

|

Additional template capabilities include:

- Submit and Run MSC Nastran jobs, retrieve results for selected checks to perform

- Creates a comprehensive and dynamic report containing:

- Executive Summary

- Detailed results of quality checks

- Standard and Custom Model Views

- E-mail report, if required, for peer or managerial review

- Execute and Publish to and from SimManager

- Completely compatible with SimManager to automate data capture and integrate into overall CAE processes

The template allows any analyst to easily filter and identify model issues, avoid mistakes and expedite model fix and reporting, reducing model preparation time and results collection from a multi-days exercise down to a few minutes, depending on the model size. In general, users can expect to see about a ten-fold improvement in process efficiencies when converting manual processes into automated templates.

Value Summary

The ability to capture, create, and automate FEA quality and model validation checks helps ensure that quality processes are followed and…

- Model validation checks can be performed in minutes, not hours or days

- Diminishes the risk of missing sometimes obvious model quality issues

- Gain high confidence in the results generated from new analysts or partners sharing models

Most importantly, it helps prevent late identification of model problems saving time, effort and simulation costs, and it helps avoid missed modeling issues which can generate incorrect results, which in turn could lead to late design and costly design fixes or even product failures in the field.

Comments

CFDpaper

Hi!

We've linked your post under http://www.cfdnewspaper.com.

Best regards,

Anthony, Crew http://www.CFDpaper.com

Christian Aparicio

Thanks.