While companies can solve automotive engine noise problems by using engine mounts to stop vibration and the firewall to stop airborne noise, these solutions are not sustainable if one wishes to maintain quality. Therefore, car manufacturers taking advantage of finite element analysis (FEA) software to better understand noise and vibration. FEA can be used to …

Category - Automotive

Understanding Automotive Engine Noise

One of the most significant pressures on car manufacturers today is sound quality. There are many factors that engineers must consider when analyzing the sound emitted by a car. Aside from being a marketing tool, there are now government regulations on sound. New developing technologies including hands-free mobile and speech recognition require the clear voice …

Automotive Noise Optimization with Simulation Software

Using Simulation Software to Predict Automotive NVH One of the most pressing challenges for today’s automotive manufacturers is to make lighter cars. A lighter car will maintain a lower level of gas consumption and thus is more eco-friendly. To achieve this goal, many companies switched from aluminum to composite materials and put smaller engines …

Identifying the Acoustic Contribution to Interior Noise

The aerodynamic sources acting on a car side window, generally defined as the small wavelength sources such as turbulent eddies and boundary layer structures, are generally much larger in amplitude than the acoustic sources, those with longer wavelengths. So naturally you would expect that the aerodynamic sources have a much greater contribution on vehicle interior …

Tuning Acoustic Quality of Audio Devices with Simulation

When designing an audio device, the most important thing for an engineer to consider is the quality of the sound. Quality is what makes the device valuable and differentiates it from competitors. Audio device manufacturing companies experience extremely high product development costs due to repetitive and expensive physical testing. In addition to the need …

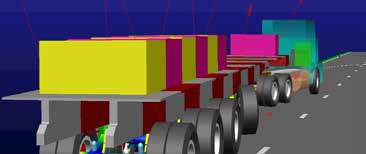

New Trailer Suspension Designs Tested in Hours Compared to Days or Weeks

Overview The primary function of heavy duty trailer suspensions is to link the trailer to its wheels. This provides a compliant connection which protects the trailer cargo from the shock and vibration inputs developed at the road surface. In addition, the suspension must meet the customers’ expectations for usable life, and do so while being …

Recent Comments